Liquid packing machine plays an important part in many industries. It can automatically fill water, pure milk, juice, vinegar, wine, and other liquids. So we can see it in numerous industries such as beverages, pharmaceuticals, wine, and so on. This packing method can greatly improve the efficiency and packaging effect. Thich is very important for the company to increase production and expand the scale. Besides, our liquid packing machine is composed of high-quality materials and has powerful functions which can fully meet your production requirements. We also offer customization on the machines for a variety of packaging unit sizes. If you are looking for an automatic liquid packing machine, welcome to contact us as soon!

Liquid Packaging Machine for Sale

The liquid packaging machine is an automatic filling machine whose function is to fill liquid products into bags, bottles, or cans. Because liquid products are easily contaminated and damaged, it is necessary to use the right packing machine to eliminate this interference. Good packaging machinery can not only ensure packaging quality and increase output, but also help the company maintain market competitiveness. As an honest packaging machine supplier, we have numerous liquid packing machines to choose from. Moreover, our machines’ special material allows them to package in wet conditions without rusting or malfunctioning. Even for packing acidic liquids like vinegar, it will not interfere with the smooth operation of our equipment. In addition, the various fillers compatible with our equipment can put almost any fluid in a flexible bag. Any interests? Please contact us directly.

Different types of Liquid Packaging Equipment

The liquid packaging machines we provide mainly have three types. The first one is the liquid lapel packaging machine, which is suitable for packing various liquids and pastes with good fluidity. The second one is a liquid filling machine, which is mainly suitable for packaging liquid products into bottles or cans. The last type is a small vertical liquid filling machine, whose main function is to pack various liquids into bags. Besides, our liquid filling equipment can be customized according to the specific conditions of your application. So no matter which type of machine you choose, you can achieve the required capacity rate for large-volume orders. Contact us and you will get an excellent machine and increase your productivity in an all-round way.

Advantages of Liquid Packaging Machine

1. The operation is simple and convenient. Workers do not need special technical training, as long as they press the start button, they can operate the machine.

2. Improve labor productivity. Fully automatic liquid packing machine packaging machinery is much faster than manual packaging. It can wrap plenty of items into bags in a short time.

3. Clean and hygiene. Reliably ensure product hygiene by eliminating hand contact with products.

4. The whole machine is made of stainless steel, which is easy to clean and maintain.

5. Stable performance. It allows long-term and continuous work and can adapt well to the high-intensity work in the workshop

6. The machine has a long service life. The parts of the machine have a reasonable structure, which is not easy to wear can start for a long time.

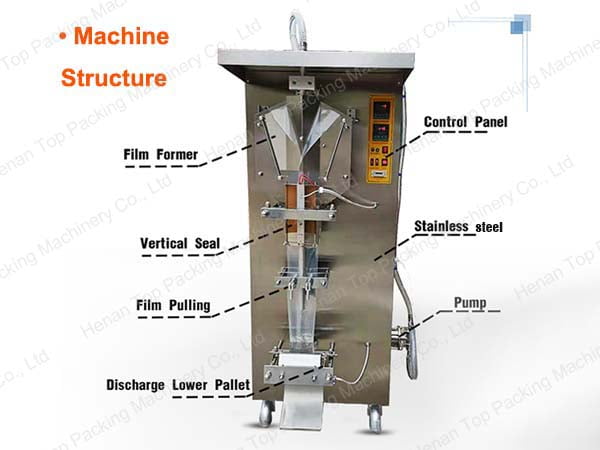

Major Components of Liquid Packaging Equipment

There are many different liquid packaging machines, and their structures also vary due to different functions and appearances. Let us take a small vertical filling machine as an example. The major components of it mainly including six parts: Control Panel, Film Former, Vertical Seal, Film Pulling, Discharge Lower Pallet, Pump.

Control Panel: It equips with an advanced control system and the operation is convenient.

Film Former: The shape and size can be adjusted according to your specific needs.

Vertical Seal: It adopts advanced sealing technology which can ensure better sealing performance.

Film Pulling: It applies to high-quality films and this film does not stick to the cutter easily.

Discharge Lower Pallet: It makes use of an automatic output conveyor for moving the products to a designated place.

Pump: It is a weighing device and also has the function of conveying liquid materials into bags.

What Does a Liquid Packing Machine Cost?

We have many different types of liquid packaging machines. And there are many factors that will affect the product pricing, such as structure, parameters, transportation costs, brand, and so on. Because these influencing factors are unstable, the price of liquid packaging machines is not fixed. Although price is a very important factor that needs to be considered when buying a product, price is not the determining factor. Many manufacturers sacrifice product quality in order to reduce prices. Although such a product saves purchase costs, it increases maintenance problems. As a trustworthy manufacturer, we never sacrifice quality to reduce costs. The liquid packing machine from us has stable performance, simple operation, and long service. At the same time, we have our own factory, so the price of us is more favorable. Welcome to get in touch with us for the best price!

How to Maintain Liquid Packaging Machine

In order to extend the service life of the liquid filling machine, we need to maintain and maintain the machine regularly. The following are the precautions:

- When the liquid packaging machine is not in use, the residual liquid in the pump should be washed with water in time, otherwise it will affect the quality of the next product.

- Regularly check the parts and lubrication conditions of the machine to ensure the normal operation of the machine.

- When the liquid packaging machine is abnormal, the power should be cut off immediately. The machine can be used again after repairing the malfunction.

- Clean the machine regularly to remove the dirty stuff scattered on the machine parts. When the machine is not used for a long time, it is necessary to cover the machine with a cloth.

Liquid Packaging Machine Manufacturers

Henan Top Packing Machinery Co., Ltd has been providing customers with superb packing machines for over twenty years. Since its establishment, the company has established a good corporate image with excellent product quality, honest work style, and perfect technical backing. There are all kinds of liquid packing machines available. And our machines actually have a great performance at providing flexible packaging for many fluids, including high and low fluidity liquids. By using a liquid filling machine, the product filling process can be easier and faster. Besides, the packaging machine we provide has been tested for a long time and has been well received by users because of its simple operation, smooth work and long service life. Looking for a good deal on a liquid packing machine? Please do not hesitate to contact us.

TH-420 Liquid Packaging Machine Parameters

| Packing speed | 5-30 bag/min | Air consumption | 0.65 mpa |

| Bag length | 80-300 mm | Gas consumption | 0.3 m³/min |

| Bag width | 50-200 mm | Dimension | 1320 mm×950 mm×1360 mm |

| Power | 2.2 kw | Weight | 540 kg |

| Voltage | 220 V | Measuring range | 5-1000 ml |

Note: customization service is available.

Packing Machine