The chips packing machine is a very important machine to increase packing speed and save the cost of chips packing. Chips are one of the indispensable snacks in people’s daily leisure. But it is crispy and easily crushed, so it has high packing requirements. In addition, the packing efficiency and effect of chips are also very important to suppliers.

Good packing can not only increase production but also help your brand stand out from many other suppliers. And for the packing of chips, there are multi-head combination weigher and tipping bucket packing machines available from us. In addition, if you have other special needs, we also provide customized services according to your ideas. Should you require further information about us, then please do not hesitate to contact us.

Different Chips Packaging Machines for Sale

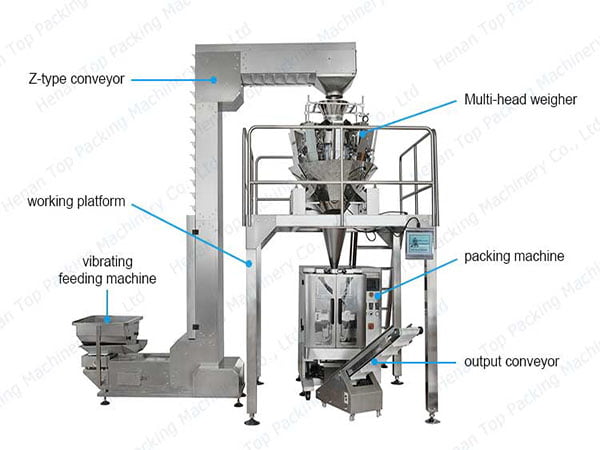

The chips packaging machine is specially designed for packing various chips or chips in the automatic production line. Only through careful packaging can chips be stored and transported for a long time. There are two types of chip packaging machines from us, one is a lapel packing machine with multi-head weigher, and the other is a tipping bucket chips packing machine.

The lapel packaging machine mainly has TH-420, TH-520, and TH-720 models. They can package bags of different sizes. Moreover, the lapel packing machine is generally used with a multi-head weigher. This can make the measurement of materials faster and more accurate.

The tipping bucket packaging machine uses a lot of tipping buckets to transport materials. Both machines can automatically complete the entire packaging process, and the packaging speed is fast. And our company has different multi-head weighers to choose from. Welcome to contact us for an intelligent and efficient chips packing machine.

Wide Applications of Chips Packing machine

The chips packing machine has a wide range of uses. It is suitable for all kinds of chips in bags, including potato chips, banana chips, apple chips, french fries, sweet potato chips, corn chips, etc. Besides, chips packing machines are also suitable for packing many other products.

For instance, a lapel packing machine is also suitable for packing puffed food, peanuts, melon seeds, candies, dried fruits, seeds, biscuits, tea, and other items. The tipping bucket chips packing machine is also suitable for automatic packaging of puffed food, beans, melon seeds, candies, preserved fruits, and other particles and powder objects with good fluidity. And there are many sealing styles available, such as three-side seal, four-side seal, back seal, continuous bag, gusset bag, etc.

Structure Details of Chips Packing Machine

Z-shape bucket elevator: The conveying speed is fast and efficient. The process of conveying materials is stable, which can reduce material loss. It can realize the functions of automatic feeding and stopping.

Multi-head weigher: The weighing speed is fast and the accuracy is high. Made of stainless steel, which can reduce product pollution.

Touch screen: Using computer control system. Setting parameters is simple and convenient. And there are multiple languages to choose from.

Working platform: It makes the operation of the machine stable and firm.

Bag maker: It can automatically roll film into packing bags through a lapel device. This can save packing costs.

Sealing device: The horizontal and vertical sealing parts are made of brass, which is evenly heated, and the sealing is firm and beautiful.

Features of Chips Packing Equipment

1. It adopts a new design with an exquisite appearance, the whole machine structure is reasonable and the production is well-made.

2. It adopts imported PLC full computer control which is convenient to operate and maintain.

3. It applies an imported servo film transport system and imported color mark sensor to ensure accurate positioning. The performance of the whole machine is stable and the packing effect is firm and elegant.

4. It has a fault diagnosis function, faults can be found in time to minimize loss.

5. The packaging bag has various shapes. There are continuous bags, three-side seals, four-side seals, back seals, etc.

6. High working efficiency. It can automatically complete the entire packaging process, reducing labor costs.

7. The circuit control is independent in the electric box, which makes the circuit more stable.

Chips Packing Machine Operation

Chips packing machines can realize the automatic process of feeding, bag making, filling, date printing, sealing, counting, and discharging. In addition, this machine has a gas-filled device. This device can flush nitrogen into the packing bag to better protect the product.

First, the bucket elevator sends the material to the hopper, the inlet can divide the material into each inlet. Then the dividing inlet sends the material to the multi-head weigher. Secondly, the weighed material is put into the bags made by the bag-forming device.

At this time, the gas-filled device can flush nitrogen into the bag. Finally, the sealing device will seal the product in many ways according to the packing requirements, then the packaged products are cut into individual bags by a cutter.

How to Maintain Chips Packing Machine?

Maintenance is essential for the long-term use of the machine. Due to the long-term and high-intensity work of the machine, the parts of the machine will inevitably receive loss. Failure to maintain the machine is equivalent to ruining the machine. The following are the precautions for maintaining the machine:

1. Check machine parts regularly. Check whether the moving parts of the machine are worn and if any defects are found, correct them in time.

2. When the machine stops working, the remaining materials in the hopper should be taken out and cleaned to prepare for the next use.

3. If the machine is out of use for a long time, it is necessary to wipe the machine and apply anti-rust oil, then cover it with a cloth.

4. Lubricate the parts regularly to ensure the stable operation of the machine and reduce the loss of parts.

Tips for Buying a Chips Packing Machine

1. Understand the characteristics of the product you want to pack, such as the size, type, shape, and packaging requirements.

2. Pay attention to whether the product needs to be inflated or pumped to maintain freshness and extend the shelf life.

3. You should understand your particular needs, including transportation requirements, customized services, environmental protection requirements, etc.

4. You also need to pay attention to the performance and structure of the packaging machine to ensure that the machine can work for a long time.

5. The cost of buying a packaging machine. When buying a packaging machine, you must compare profit and investment to ensure that you can make a profit.

Why to Choose Us as Your Supplier?

Henan Top Packaging Machinery Company is a professional supplier of packing equipment and packing production lines. For over 20 years, our company has been developing flexible and efficient packing equipment for a variety of industries.

We have accumulated rich manufacturing experience and industry experience. As long as you have product packing needs, we can engineer a custom solution that can solve your problems with an efficient packing solution.

At present, our main products are granule packaging machines, vacuum packaging machines, liquid packaging machines, labeling machines, capping machines, and other packaging machinery packaging equipment.

And our products sell well at home and abroad with excellent quality and preferential prices. If you are looking for an efficient and automatic chips packing machine, please contact us as soon as possible.

Packing Machine