La machine d'emballage thermo-rétrécissant applique le film rétractable étroitement sur les surfaces du produit, offrant une protection contre la poussière et l'humidité et assurant une seals. Elle est largement utilisée dans des industries telles que l'alimentation, les boissons, les produits pharmaceutiques, les produits de consommation courante et les cosmétiques.

La machine d'emballage Taizy convient aux films rétractables tels que POF, PVC et PE. Elle offre une vitesse d'emballage de 15-30 pièces par minute et une plage de température de rétrécissement de 0-300°C. Si vous êtes intéressé par cette machine, n'hésitez pas à nous contacter !

Caractéristiques exceptionnelles de la machine d'emballage à film rétractable

- La machine d'emballage par rétrécissement thermique convient pour emballer des films rétractables tels que POF, PVC et PE.

- La machine d'emballage par rétrécissement thermique Taizy possède une Niveau élevé d'automatisation, en complétant automatiquement les processus de laminage, de scellage, de coupe et de rétrécissement.

- La bande transporteuse de la machine d'emballage thermique automatique Taizy est résistant à la chaleur et non destructif.

- La température de rétrécissement de notre machine d'emballage par film rétractable peut être ajusté en fonction de l'épaisseur du film.

- Elle produit emballage beau et soigné, renforçant l'identité du produit.

- Les produits emballés sont efficacement protégé de la poussière, de l'humidité et des impacts extérieurs.

Application de la machine d'emballage thermo-rétrécissant

Les machines d'emballage rétractif Taizy ont une large gamme d'applications, couvrant les besoins d'emballage de presque tous les secteurs :

- Industrie alimentaire: Nouilles instantanées, boissons, eau minérale, conserves, condiments, biscuits, gâteaux, etc.

- Industrie des produits de consommation courante: Cosmétiques, détergents, papeterie, jouets et artisanat.

- Industrie des produits pharmaceutiques et de la santé: Emballage pharmaceutique, dispositifs médicaux et aliments santé.

- Industrie des produits électroniques: Télécommandes, écouteurs, câbles, batteries et petits appareils.

- Produits industriels: Bouteilles de lubrifiant, bidons de peinture, accessoires de quincaillerie et outils.

- Logistique et emballage complet en caisse: Caisses de boissons, livres, magazines et cartons.

Structure et paramètres de la machine d'emballage rétractif

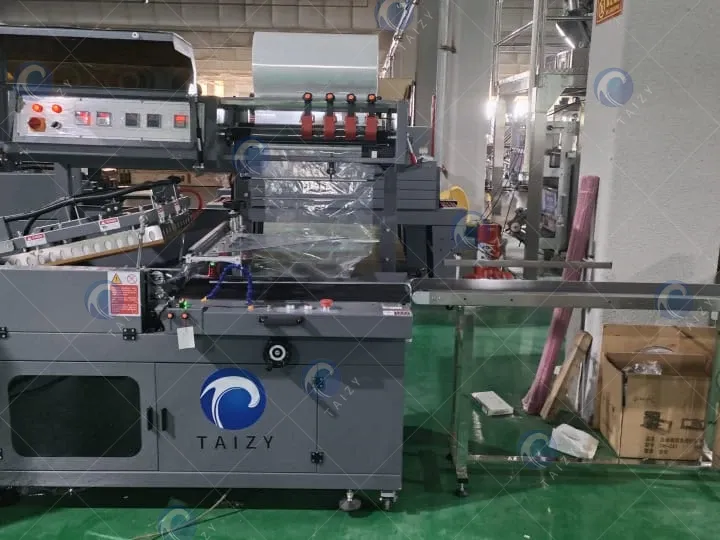

Une machine d'emballage thermo-rétrécissant complète comprend généralement deux composants : la machine de scellement et de coupe en forme de L et le tunnel de rétraction par chaleur.

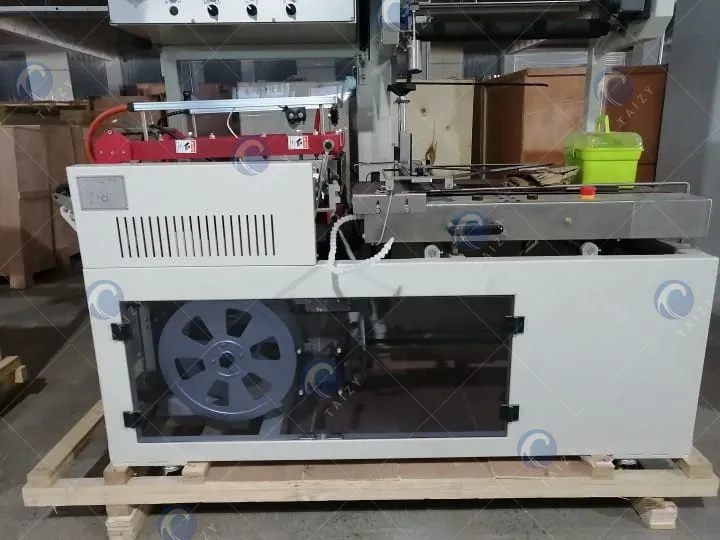

Machine de scellement et de coupe en forme de L

Sa fonction principale est de placer les produits dans le film rétractable et d'utiliser une lame de scellement chauffée pour couper et sceller le film. Il fonctionne avec une grande efficacité, produisant des coupes propres et esthétiques. Ses paramètres spécifiques sont les suivants :

| Modèle | TZ-450L | TZ-550L | TZ-750L |

| Tension (V/Hz) | 220V 50-60Hz | 220V 50-60Hz | 220V 50-60Hz |

| Puissance (kW) | 1.6 | 1.86 | 2.26 |

| Vitesse d'emballage (sacs/min) | 15-30 | 15-30 | 15-30 |

| Pression d'air (Mpa) | 0.5 | 0.5 | 0.5 |

| Charge de convoyage (Kg) | 15-20 | 15-20 | 15-20 |

| Dimensions maximales d'emballage (mm) | L+2H≤550mm, P+H≤35mm, H≤140mm | Largeur + Hauteur ≤ 500, Longueur + Hauteur ≤ 60, Hauteur ≤ 150 mm | Largeur + Hauteur ≤ 700, Longueur + Hauteur ≤ 80, Hauteur ≤ 150 mm |

| Taille du coupeur (mm) | 570*470 | 650*570 | 870*770 |

| Taille de la machine (mm) | 1700*880*1470 | 1900*1100*1500 | 2250*1180*1475 |

| Film rétractable adapté | POF | POF | POF |

| Largeur de la chaîne (mm) | 330 | 430 | 600 |

| Poids (Kg) | 291 | 334 | 440 |

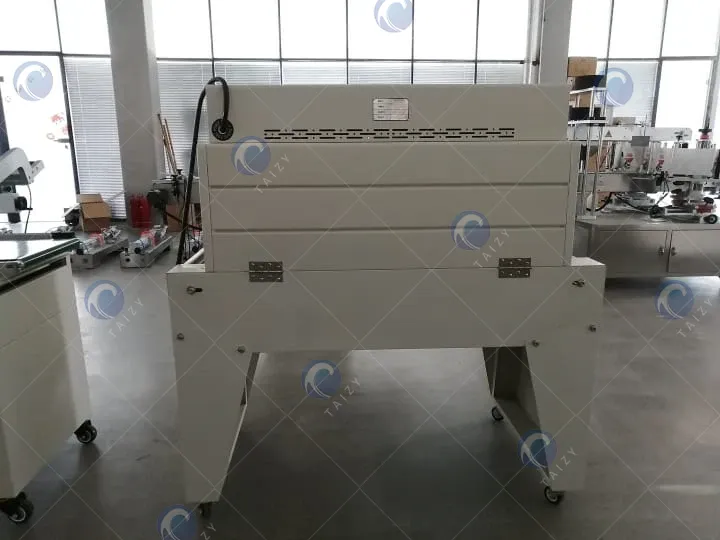

Tunnel rétractif par chaleur

Après être emballé par la machine de scellement et de coupe, le produit entre dans le tunnel rétractif par chaleur. L'air chaud circulant réchauffe le film rétractable, provoquant son rétrécissement uniforme et son adhérence serrée à la surface du produit.

La machine d'emballage thermo-rétrécissante offre non seulement une grande transparence mais aussi d'excellentes propriétés d'étanchéité, protégeant efficacement contre la poussière et l'humidité. Ses spécifications sont les suivantes :

| Modèle | TZ-4522 | TZ-5530 | TZ-7535 |

| Tension d'alimentation (V/Hz) | 220-380V 50-60Hz | 220-380V 50-60Hz | 220-380V 50-60Hz |

| Puissance (kW) | 15 | 16 | 24 |

| Taille de la machine (mm) | 1900*710*1260 | 1900*810*1320 | 2200*1010*1420 |

| Vitesse de transport (m/min) | 0-15 | 0-16 | 0-15 |

| Charge de transport (Kg) | 20 | 20 | 40 |

| Film rétractable adapté | PVC/POF | PVC/POF | PVC/POF |

| Poids de la machine (Kg) | 200 | 230 | 336 |

Le prix de la machine d'emballage par film rétractable

Le prix d'une machine d'emballage thermo-rétrécissante est principalement influencé par les facteurs suivants :

- Taille d'emballage et production: Des tailles de produits plus grandes et des vitesses de production plus élevées nécessitent un équipement de haute spécification, entraînant une augmentation de prix correspondante.

- Configuration de l'équipement: Les coûts sont influencés par le degré d'automatisation, comme l'inclusion d'une scelleuse et d'une coupe en forme de L entièrement automatique, la possibilité de fonctionnement continu, et la présence d'un système de contrôle de température intelligent.

- Configuration supplémentaire: Si vous avez besoin de configurations supplémentaires, comme des dispositifs auxiliaires tels que des imprimantes à jet d'encre ou des machines d'étiquetage, le prix augmentera en conséquence.

Si vous souhaitez connaître le devis spécifique pour la machine d'emballage thermo-rétrécissant, n'hésitez pas à nous contacter. Vous n'avez qu'à fournir les spécifications de votre produit et vos exigences d'emballage, et nous recommanderons des modèles adaptés et proposerons la solution la plus rentable.

Pourquoi choisir Taizy comme fournisseur ?

Choisir nos machines d'emballage par rétraction signifie obtenir non seulement une pièce d'équipement très efficace, mais aussi choisir un partenaire fiable :

- Ventes directes en usine: La production et la vente intégrées éliminent les intermédiaires, offrant des prix plus compétitifs.

- Assurance qualité: Des composants haut de gamme et un contrôle qualité rigoureux garantissent une machinerie stable et durable.

- Gamme complète de produits: Au-delà de la machine d'emballage par rétrécissement thermique, nous fournissons également machine à emballage en coussin, machine d'emballage de granulés, Machine d'emballage de poudre, et plus encore.

- Solutions diverses: Que ce soit pour un emballage en petite série ou des lignes de production automatisées à grande vitesse, nous proposons des solutions sur mesure.

- Support après-vente complet: Notre équipe technique fournit des conseils d'installation, une formation opérationnelle et un support de maintenance à long terme, garantissant une tranquillité d'esprit totale.

- Fait confiance à des clients du monde entier: Notre équipement est exporté vers de nombreux pays et régions, recevant la reconnaissance et la renommée d'une large clientèle.

Si vous recherchez une machine d'emballage, merci de nous contacter avec les détails de vos matériaux d'emballage et exigences, nous recommanderons l'équipement d'emballage le plus adapté à vos besoins !