The liquid packing machine is specially designed for a variety of liquids. It can be used to package liquids such as water, juice, and vinegar. Our liquid filling machine integrates bag forming, filling, counting, sealing, slitting, and output, resulting in high packaging efficiency.

Taizy liquid filling and packaging machine has a packaging speed of 20-60 bags/min and can pack up to 1000ml of liquids. This liquid packaging machine can also be equipped with a ribbon or steel stamp coding device. If you are interested in our machines, please contact us for detailed information.

Why is Taizy liquid packaging machine so popular?

Our liquid packaging machine is very popular in various regions and has been exported to India, Nigeria, Canada, and other regions. Our water packaging machine is popular because it has the following advantages:

- Simple and convenient operation. Workers do not need special technical training; they simply press the start button to operate the machine.

- Improved productivity. The fully automatic liquid packaging machine is faster than manual packaging, with a packaging speed of up to 80 bags/minute.

- Clean and hygienic. The entire machine is made of stainless steel, making it easy to clean and maintain.

- Stable performance. This liquid packing machine can run continuously for a long time and is suitable for high-intensity operations in the workshop.

- Long service life. The machine’s components are rationally constructed, highly wear-resistant, and can be used for extended periods of time.

Liquid Packaging Machine for Sale

As a reliable packaging machine supplier, we offer two types of liquid packaging machines:

Type 1: Fully automatic liquid packaging machine

Type 2: VFFS liquid packaging machine

Type 1: Fully automatic liquid filling and sealing machine

This machine uses heat-sealable plastic films such as polyethylene or PE, and the packaging form is back seal(special requirements can be customized).

The liquid bag packaging machine has a packing speed of 20-40 bags/minute and a packing range of 50-1000ml.

It has two models: the SJ-1000 and the SJ-2000. Its specific parameters are shown in the following table.

| Model | SJ-1000 | SJ-2000 |

| Bag length | 50-150mm | 50-250mm |

| Bag width | 40-150mm | 40-175mm |

| Packaging capacity | 50-500ml | 200-1000ml |

| Packing speed | 2000-2200bags/h | 1100-1300bags/h |

| Power | 1.6kw | 2.5kw |

| Machine size | 880*760*1800mm | 1050*850*2050mm |

| Machin weight | 275kg | 380kg |

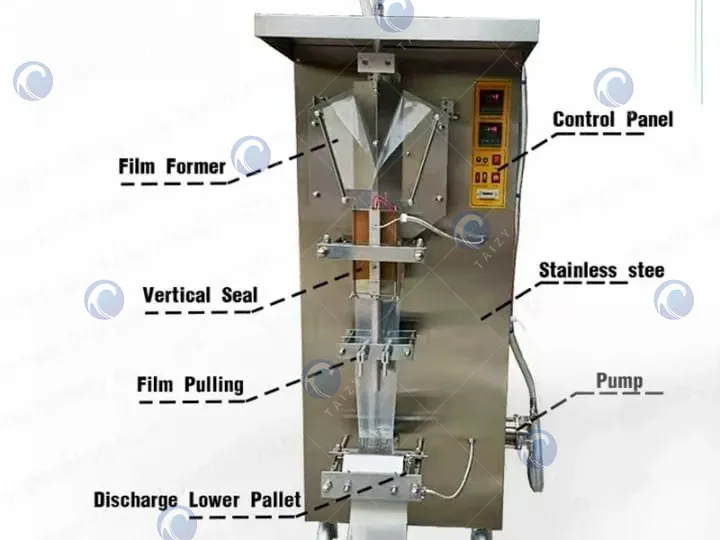

Structure of the liquid packing machine

The fully automatic liquid bag packaging machine is mainly composed of control panel, film pulling device, recirculation device, ribbon coding machine, heat-sealed insulation cloth.

- Control panel: Fully automatic blanking, sealing, coding, counting, feeding, temperature control, bag length, cutting, and metering. Photoelectric control enables integrated, fully automatic packaging.

- Film pulling device: Vertical film drawing device precisely controls bag length and ensures a thorough seal.

- Recirculation device: When the machine is operating, the yellow valve opens to allow excess liquid to flow back.

- Ribbon coding machine: Automatically codes packaging bags.

- Heat-sealed insulation cloth: The PE film is thin and does not come into direct contact with the cutter(both horizontal and vertical sealing are possible).

Type 2: VFFS liquid filling and sealing machine

The liquid packing machine offers two popular models: the TZ-320 and the TZ-450. This machine has a packaging speed of 20-80 bags/min.

This juice packing machine can pack liquids in back-seal, 3-side seal, and 4-side seal modes.

It consists of a pump and a packaging system, with either conventional pump or magnetic pump available.

| Modle | TZ-320 | TZ-450 |

| Packing speed | 20-60bags/min | 30-80bags/min |

| Bag length | 30-200mm | 20-200mm |

| Bag width | 25-145mm | 30-300mm |

| Feeding methods | Gravity feeding system | Gravity feeding system |

| Power | 1.8kw | 2.2kw |

| Machine size | 650*850*1850mm | 750*750*2100mm |

| Machine weight | 250kg | 420kg |

Applications of liquid packing machine

Taizy liquid bag packaging machine is widely used in the liquid industry. It can be used to package various liquids without particles, such as purified water, mineral water, oil, juice, milk, vinegar, wine, etc.

How to maintain liquid bag packaging machine?

In order to extend the service life of the liquid packing machine, we need to maintain and maintain the machine regularly. The following are the precautions:

- When the liquid packaging machine is not in use, the residual liquid in the pump should be washed with water in time; otherwise, it will affect the quality of the next product.

- Regularly check the parts and lubrication conditions of the machine to ensure the normal operation of the machine.

- When the liquid packaging machine is abnormal, the power should be cut off immediately. The machine can be used again after repairing the malfunction.

- Clean the machine regularly to remove the dirt scattered on the machine parts. When the machine is not used for a long time, it is necessary to cover the machine with a cloth.

What does the liquid packing machine cost?

Many factors influence the pricing of the liquid packaging machine, including structure, specifications, shipping costs, and brand. Because these factors fluctuate, the price of the liquid filling machine is not fixed.

While price is an important factor to consider when purchasing a product, it is not the decisive factor. When purchasing the liquid packaging machine, consider not only the price but also the quality of the machine.

As a trusted manufacturer, Taizy produces the liquid sachet packaging machine with stable performance and a long service life. Furthermore, we own our own factory, resulting in more competitive prices. If you would like to inquire about pricing details, please contact us! Welcome to get in touch with us for the best price!

Why choose Taizy as your supplier?

As a packaging machine supplier, Taizy has consistently provided customers with superior packaging machines. In addition to liquid packing machine, we also offer powder packaging machine, paste packaging machine, granule packaging machine, and tea packaging machine.

Since our founding, we have established a strong reputation for superior product quality, integrity, and comprehensive technical support. Our clients have consistently expressed their satisfaction with our machines and services. If you require any assistance, please feel free to contact us!