The yogurt cup filling machine is a fully automatic production machine that integrates automatic cup feeding, filling, sealing, and cup discharging. The yogurt cup filling and sealing machine features a stainless steel body, ensuring a clean and hygienic design.

Taizy yogurt filler is not only suitable for yogurt but also for other products such as coffee liquid and dried fruit. This equipment can pack 800-1800 cups per hour. And its filling volume ranges from 50-500ml, making it suitable for businesses of all sizes. If you are interested, contact us for a free consultation.

Advantages of yogurt cup filling equipment

- High degree of automation: The yogurt cup filling machine can automatically complete cup feeding, filling, sealing, and taking out the finished product.

- Easy to operate: The machine parameters can be set directly on the touch screen, which is simple and easy to operate.

- Precise filling: Its piston-type quantitative filling system ensures consistent filling volume for each container, preventing overflow or underfill.

- Long service life: Taizy yogurt filling machine is made of stainless steel, which is clean, hygienic, and has a long service life.

- Highly intelligent: Our yogurt filling and sealing equipment automatically stops when it detects a cup is empty and restarts when a cup is refilled.

Application of rotary filling machine

The cup filling and sealing machine is suitable not only for yogurt but also for a wide variety of products, such as fresh milk, milk tea, juice, jelly, lassi, curd, purified water, mineral water, coffee, juice, sauce, jam, and more. And it is suitable for plastic cups, paper cups, aluminum plastic cups, etc.

Parameters of yogurt filling sealing machine

Our yogurt cup filling machine is available in two types: the rotary yogurt filler machine and the linear yogurt filling equipment. The rotary yogurt filling and sealing machine is the best-selling model.

The rotary yogurt filling and sealing machine has two models: single outlet filling equipment and double outlet yogurt filler machine. Its specific parameters are as follows:

| Model | KIS-1800 |

| Packaging speed | 800-900cups/h (single outlet) 1600-1800cups/h (double outlet) |

| Power | 220V 1.2KW |

| Air pressure | 0.5-0.75Mpa |

| Maximum air consumption | 0.45m3/m |

| Machine size | 100*80*120cm |

| Machine weight | 350kg |

The structure of yogurt canning machine

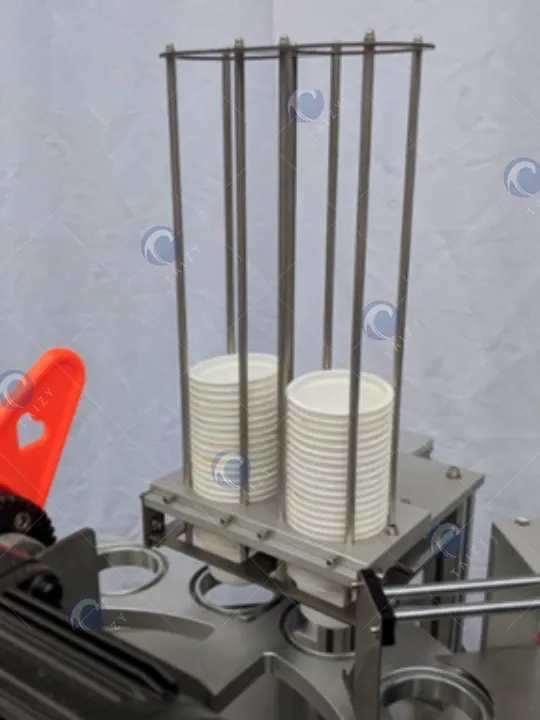

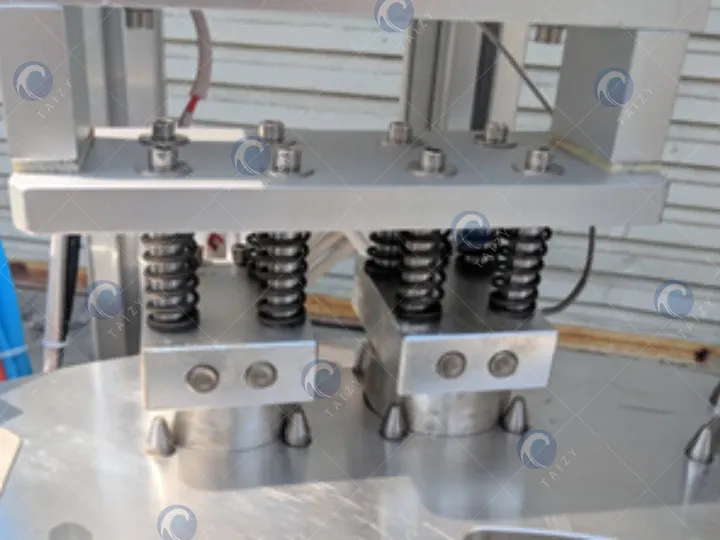

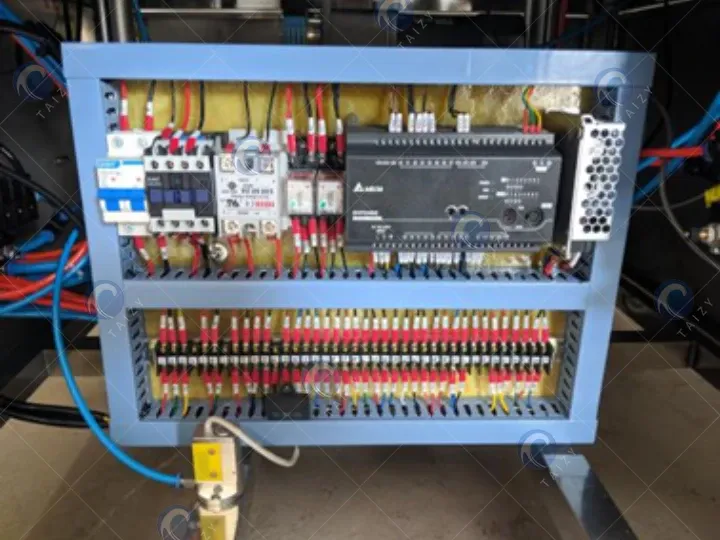

The yogurt cup filling machine consists of PLC touch screen, sealing system, automatic filling system, automatic cup dropping system, automatic film releading system, and automatic cup discharging system.

Working principle of yogurt cup filler

The yogurt cup filling machine relies on the coordinated operation of electrical, pneumatic, and mechanical systems to continuously operate in the sequence of “cup drop – filling – film application – sealing – cup discharge,” achieving fully automatic, efficient, safe, and hygienic yogurt cup filling.

- System startup: After the electrical control system is powered on, the drive motor, pneumatic system, and transmission begin operation.

- Automatic cup drop: The pneumatic system drives the cup-dispensing mechanism, accurately dropping empty cups into aluminum molds.

- Automatic quantitative filling: The piston-type quantitative filling device activates, precisely pouring the set volume (50–500ml) of yogurt into the cup.

Automatic film placement: The automatic film placement device precisely applies the sealing film to the cup rim. - Heat sealing: Under constant temperature, the heat sealing device, driven by a pneumatic actuator, presses the heat sealing head downward, securely sealing the film to the cup rim.

- Automatic cup discharge: The finished cup is ejected by the cup-dispensing device and transported out via the output conveyor.

FAQ of yogurt cup filling sealing machine

What type of film is it?

There are two types of film: roll film and sheet film.

Is there a limit to the diameter of the cup?

The diameter should be within 95mm. If it exceeds 95mm, you can only use the rotary yogurt filling machine(single outlet) or the linear yogurt filler equipment.

Can different cup sizes be used on the same machine?

The same machine can be used for different heights; different diameters require customized molds.

Can the print date function be customized?

The date printing function can be customized and can be printed on the film or the cup body. It needs to be used with a conveyor belt. The conveyor belt needs to be at least one meter long.

Why choose Taizy yogurt cup filler machine?

Taizy is a strong packaging machinery manufacturer and supplier with over a decade of experience. Our machine is technologically advanced, utilizing control systems and pneumatic components from renowned brands, ensuring low failure rates, stable performance, and a long service life.

In addition, our machine is comprehensive. Besides the yogurt cup filling machine, we also offer granule packaging machine, powder packaging machine, tea packaging machine, and more. If you’re interested, contact us for a free quote.