Our client is from Nigeria. He is the head of a local tea production and sales company. He hopes to improve the efficiency and standardization of production through the automated tea packaging machine, thereby enhancing the market competitiveness of his company’s products.

Through communication, we learned the customer’s specific requirements: a three-sided seal. Furthermore, the customer was very concerned about the machine quality and delivery. Based on this requirement, we recommended the 10-40g tea pouch packaging machine.

Customer challenges and requirements

The customer stated that their existing tea pouch packaging machine was cumbersome to operate and inefficient. Therefore, they requested the following features from our tea sachet packing machine:

- User-friendly: The tea packaging machine should be easy to operate and require no extensive training.

- Fast packaging speed: The daily production volume should reach over 8,000 bags.

- High packaging accuracy: The weight tolerance of each tea bag should be controlled within ±1g.

- Good machine quality: The machine should meet quality standards and undergo a pre-delivery test.

- Voltage compatibility: the customer’s location uses 220V/50Hz single-phase electricity, and the equipment must be compatible with local standards.

Our proposed solution

Based on the customer’s needs, we recommended the Taizy tea packaging machine to the customer, which has the following features:

- Packing weight: This tea packer can pack tea bags ranging from 10 to 40 grams, meeting all specifications.

- Packaging speed: Taizy tea filling and packing machine can produce 30 to 100 bags per minute, enabling large-scale production.

- Bag sealing method: This machine uses a three-sided seal method, ensuring a strong seal and product quality.

- Voltage compatibility: Customizable 220V/50Hz single-phase power configurations are available to meet customer needs.

Successful order

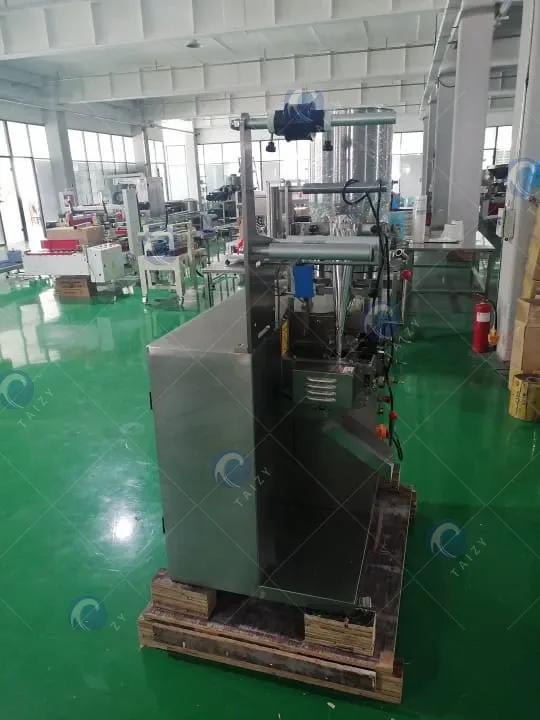

After our introduction, the customer expressed satisfaction and paid a deposit. We then immediately began production of the tea packaging machine. After the inner tea bag packing machine was completed, we tested it and sent the test video to our customer. The customer expressed satisfaction and paid the balance.

Packaging and Shipping

In order to ensure that the machine will not be damaged during transportation, we have carefully packed the machine. We first wrap the machine in plastic wrap and then pack it in a wooden box to ensure it is not damaged during transportation.

Normally, we ship the machine by sea, and we have a stable shipping company that we work with to ensure the machine arrives on time. If you want to know more about the tea packaging machine, please contact us immediately.